DARWEEN – Data Acquisition and Processing Framework for the Efficient Ecological Assessment of Manufacturing Systems

Principal Investigators: Dr.-Ing. Susanne Vernim (TUM), Prof. Xavier Delorme (IMT); Other contact person; Patrick Jordan (TUM), Ass. Prof Damien Lamy (IMT)

Short summary and central question:

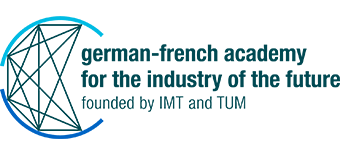

Recently, the European Commission presented a proposal to amend the CSR Directive, which will put sustainability reporting on an equal footing with financial reporting. In addition, as part of the regulation for an eco-design for sustainable products, a framework to set ecodesign requirements for sustainable products has been initiated (EUROPEAN COMMISSION 2022) to provide consumers with better transparency in their purchasing decisions. In this context, several environmental parameters, such as the amount of used recyclable materials and substances, the consumed energy, generated waste and emissions as well as the environmental and carbon footprint, were determined as a basis for the evaluation of products. In contrast to indicators of production performance, the necessary data for an environmental assessment are as of now not recorded continuously but only for specific cases, such as the need for certification (FERRARI ET AL. 2021). This is especially due to the time-consuming data collection during the Life Cycle Assessment and the required expertise to identify the needed parameters (MEINRENKEN ET AL. 2012). With a variety of possible metrics and scoring systems, companies are unsure how and which parameters must be gathered to meet regulatory data needs in the production environment. The aim of the project is therefore to develop a framework that supports companies in deciding which data should be recorded at which location in a production company in order to collect all the necessary ecological information of a product as efficiently as possible. The central question that is to be answered in the context of this project is therefore: How must a framework be designed to support manufacturing companies in deciding which data for the ecological evaluation of products and its manufacturing processes should be gathered at which location in the company and how can the data gathering be designed as efficiently as possible?

Overview of the state-of-the-art

While several research projects address environmental factors and KPIs, such as energy minimization (LAMY ET AL. 2020, GIANESSI ET AL. 2021), the used parameters mostly rely on built data, as collecting and identifying relevant ones is challenging. For the evaluation of the ecological impact of a product, the procedure of a life cycle assessment study is used, which is regulated, among others, in ISO 14040, which is one of the most well-known standards. In four phases, the scope of the LCA study is defined, the necessary data are recorded in the life cycle inventory (LCI) phase, an impact assessment (LCIA) is carried out, before an evaluation is performed finally (ISO 14040 2021). While the methodological procedure is already regulated by ISO 14040, there is a lack of standards for the necessary accuracy in data recording, which is why current LCA studies in research have different levels of detail and companies are unsure about what data to include in their assessments. 4 Moreover, small companies in particular lack the necessary expertise and investment to carry out data collection in a targeted manner, which is why LCA is often only carried out in larger companies (SUREEYATANAPAS ET AL. 2021). Due to the complexity of performing an LCA, simplification has become a widely used approach. Particularly relevant simplification logics are exclusion, inventory data substitution, qualitative expert judgements, standardization and automation (BEEMSTERBOER ET AL. 2020). Simplification makes it easier for companies to perform LCAs, but it leads to a loss of information, is dependent on trained experts, and still requires the recording and assessment of basic data. Therefore, in conjunction with stricter regulations and the goal of increasing LCA automation, data collection during LCI remains one of the biggest barriers in ecological assessments.

Objectives of the project

The overall objective of the project is the development of a framework that supports manufacturing companies in the data gathering of ecological parameters by identifying and classifying the appropriate data needs. In addition, the required data gathering should be optimized by identifying suitable methods, that could be applied in an increasingly networked production environment. These goals are intended to further integrate the issue of sustainability into the digital transformation of manufacturing companies. The project objective comprises the following sub-goals:

- Development of a parameter catalogue containing the relevant data needs for determining the ecological impacts of manufacturing processes in mechanical and plant engineering

- Description of a classification system for the identified parameters in terms of the need for data recording in the manufacturing process or at plant level in relation to the maturity phase of manufacturing processes

- Proposition of a framework that companies can use to structure the identification of necessary ecological parameters and their collection

- Identification of technological possibilities for data acquisition of individual parameters

- Design of a roadmap to enable companies to apply the framework in their business context

Expected impact on academia, industry and society

As the society influences consumer-driven sustainability measures throughout the supply chain (MORAN ET AL. 2020), producing products with a reduced ecological impacts can become a key competitive advantage for manufacturing companies. The reduction of a product’s ecological impact enables companies to promote product differentiation and to enhance a company’s brand image (SUREEYATANAPAS ET AL. 2021). At the same time, the pressure on companies to determine their ecological impact continues to increase due to stricter regulations. For this reason, the assessment of the ecological impact is not only a potential competitive advantage but also a risk at the same time.

To support companies in the challenge of ecological assessments and thus the transformation to a more sustainable society, a targeted data collection in production processes is required, for which the basis is to be laid within the framework of this research 5 project. Optimizing data analysis makes life cycle assessment easier for companies and leads to increased transparency in products.

The identification of the necessary parameters supports science in the development of a standardized procedure in the ecological assessment of products and thus leads to a better comparability of further studies. Furthermore, the procedure developed on the basis of the identified ecological parameters in manufacturing processes can be transferred to other relevant areas like the assembly or transportation processes and thus leads to more transparency in the different assessment methods.

P